Our worldwide presence ensures the timeliness, cost efficiency and compliance adherence required to ensure your production timelines are met.

Call Us

+88 02 5508 6766Call Us

+88 02 5508 6766Product Features

High Safety and Reliability

A large space furnace with exceptional thermal expansion capability is utilized by the steam evaporator in the combustion chamber, along with an explosion door. To ensure the safe operation of the steam evaporator, the body is equipped with highly sensitive sensors for temperature, pressure, and water level. The controller establishes a highly dependable multiple safety protection control system.

High Efficiency and Energy Saving

The steam evaporator adopts the structure of large furnace chamber, which increases the area of radiant heat transfer and facilitates the full combustion of fuel. By utilizing the fuzzy control technology based on artificial neural network and world well-known brand burner, it realizes fully automatic adjustment of combustion according to temperature pressure and time, so that the steam evaporator can operate efficiently and economically under different conditions while minimizing fuel consumption.

Green Manufacturing

The structure of the steam evaporator is designed with low NOX combustion technology to maximize efficiency. Flue gas detection is used to automatically adjust the combustion condition of steam evaporator, ensuring that both low operation noise and flue gas emissions comply with Bangladesh's environmental protection regulations.

Practicability

Over-pressure interlock protection: The burner will not operate and an alert will sound if the internal pressure of steam evaporator rises above the predetermined level.

Leakage protection: In the event that it detects an electrical element leak, the control system will immediately turn off the power.

Protection against water shortage: When the controller detects a water shortage, it cuts off the burner's control circuit in time to save it from being damaged by dry burning.

Over-current protection: In the case that the steam evaporator is overloaded (high voltage), the leakage circuit breaker will automatically disconnect.

Unattended: After starting up, there is no requirement for personal operation; long-term operation simply requires appropriate supervision.

Multiple Applications

It can be used to produce steam at lower steam consumption for factories that food processing, print and dye, garment manufacturing, pharmaceuticals manufacturing, supply steam to scientific research institutes, and so on. It can also be used to sterilize steam for hospitals, produce steam for other enterprises and hotels, and heat tanks to provide hot water for domestic use.

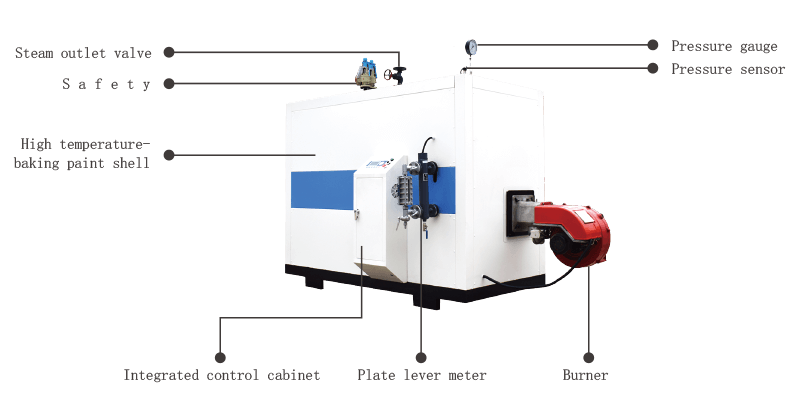

Structure Diagram of Oil/Gas-Fired Steam Evaporator

Technical Parameters and Installation Diagrams

Technical Parameters | 0.5T/hr Gas/Oil-fired Steam Evaporator | 1.0T/hr Gas/Oil-fired Steam Evaporator | 2T/hr Gas/Oil-fired Steam Evaporator | |||

Model | WSS0.5-0.7-Q | WSS1.0-0.7-Q | WNS2.0-0.09-Y.Q | |||

Rated Working Pressure | 0.7 Mpa | 0.7 Mpa | 0.09 Mpa | |||

Rated Steam Temperature | 170 °C | 170 °C | 118 °C | |||

Thermal Efficiency | ≥96% | ≥96% | ≥96% | |||

Water Capacity | 29 L | 29 L | / | |||

Diameter of Safety Valve | DN32 | DN32 | DN40 | |||

Outlet Diameter of Steam | DN32 | DN40 | DN40 | |||

Inflow Diameter of Water | DN32 | DN32 | DN40 | |||

Diameter of Draining Valves | DN32 | DN32 | DN40 | |||

Chimney Diameter | 219 mm | 219 mm | 330 mm | |||

Inlet Diameter of Gas | DN32 | DN40 | DN50 | |||

Supply Pressure of NG | 4-6 Kpa | 6-8 Kpa | 6-8 Kpa | |||

Overall Size of Product | 1950mm*1200mm*1600mm | 2900mm*1300mm*2000mm | 3600mm*1800mm*2400mm | |||

Transport Weight | 1.6 T | 3.2 T | 4.2 T | |||

Fuel Consumption | NG | 37 m3/h | NG | 74 m3/h | NG | 148 m3/h |

LPG | 28 kg/h | LPG | 54.5 kg/h | LPG | 109 kg/h | |

Product Configuration | Control System*1, Primary Instrumentation Valve*1, Vertical Multi-stage Stainless Steel Water Pump*1, Economizer*1 | Control System*1,Primary Instrumentation Valve*1, Vertical Multi-stage Stainless Steel Water Pump*1, Economizer*1 | Control System*1, Primary Instrumentation Valve*1, Vertical Multi-stage Stainless Steel Water Pump*1, Burner 1, Economizer*1 | |||