Our worldwide presence ensures the timeliness, cost efficiency and compliance adherence required to ensure your production timelines are met.

Call Us

+88 02 5508 6766Call Us

+88 02 5508 6766H.E. ≥ 95% | NOX ≤30 mg/m3 | Fuel (1 T/h) 160 m3/h |

Product Features

Less water capacity and quick steam production to match customer demands.

Fuel selection biomass granule with lower water content.

A circinate large-capacity steam chamber located at the upper part of the machine and steam-water separation measures inside the pot ensure to produce high-quality dry steam at all times.

Protection device for extremely low water level is incorporated into the boiler body to detect changes of the water level inside the furnace body at any time, preventing safety mishaps and the furnace body from burning dry.

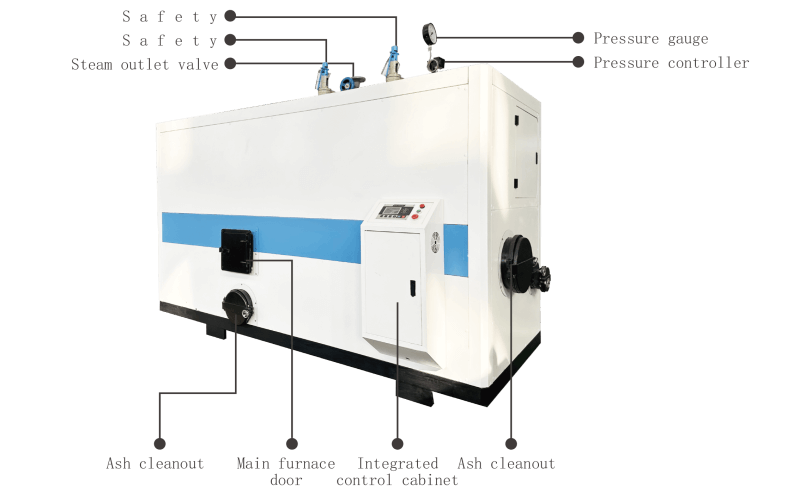

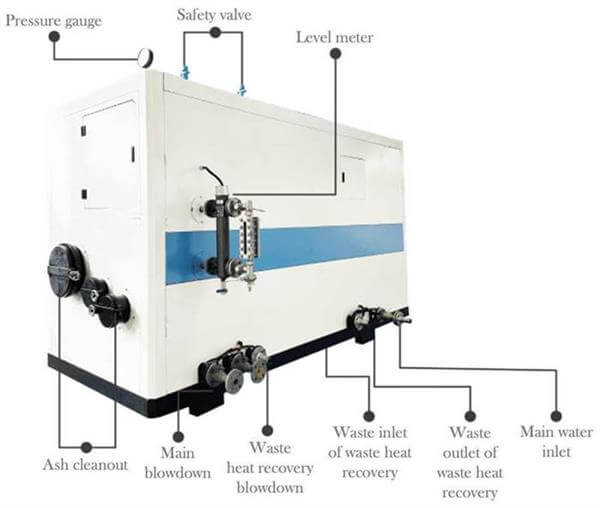

The steam evaporator is outfitted with superior quality safety valves, shut-off valves, level meters, electrodes, pressure gauges and pressure controllers and additional safety accessories to guarantee dependable operation.

Equipped with high quality water level meter, the water level of the steam evaporator is clearly recognizable.

An economizer is integrated into the tail flue allows for waste heat recovery and enhances thermal efficiency.

The furnace chamber adopts internal combustion and horizontal three-way full water fire tube structure that strengthens convection heat transfer to make it produce steam quickly and have compact and beautiful appearance, small footprint.

Protection Application

Over-pressure Interlock Protection: The burner will be prohibited from operating and alarmed when the pressure inside the steam evaporator exceeds the predetermined value.

Leakage Protection: The control system will immediately cut off the power supply upon detecting electric element leakage.

Water Shortage Protection: In the case of the steam evaporator running out of water, the controller alert will sound, timely cutting off the control circuit of the burning system to prevent damage and dry burning.

Over-current Protection: In the case of the steam evaporator being overloaded (high voltage), the leakage circuit breaker will automatically disconnect.

Product Application

To provide production steam for food processing factories, printing and dyeing, garment manufacturing, pharmaceuticals, scientific research institutes and so on, to provide sterilization steam for hospitals, to provide steam for other enterprises and hotels, and to heat tanks to provide hot water for daily use.

Technical Parameters and Installation Diagrams

Technical Parameters | 0.5 T/hr Biomass-fired Steam Evaporator | 1.0 T/hr Biomass Steam Evaporator | Chain-grate Boiler |

Model | WSS0.5-0.7-S | WSS1.0-0.7-S | WNS2.0-0.09-S |

Rated Working Pressure | 0.7 Mpa | 0.7 Mpa | 0.09 Mpa |

Rated Steam Temperature | 170 °C | 170 °C | 118 °C |

Thermal Efficiency | ≥95% | ≥95% | ≥95% |

Water Capacity | 29 L | 29 L | / |

Diameter of Safety Valve | DN32 | DN32 | DN40 |

Diameter of Steam Outlet | DN32 | DN40 | DN40 |

Diameter of Water Inflow | DN32 | DN32 | DN40 |

Draining Valves Diameter | DN32 | DN32 | DN40 |

Chimney Diameter | 219 mm | 273 mm | 330 mm |

Overall Size of Product | 2400mm*1200mm*1800mm | 3400mm*1360mm*2300mm | 3900mm*1800mm*2800mm |

Transport Weight | 1.5 T | 2 T | 5.4 T |

Fuel Consumption | 80 kg/h | 160 kg/h | 320 kg/h |

Product Configuration | Control System*1, Feed system*1, Blower*1, Induced Draft Fan*1, Wet Dust Collection*1, Economizer*1, High -pressure Pump*1 | Control System*1, Feed System*1, Blower*1, Induced Draft Fan*1, Wet Dust Collection*1, Economizer*1, High -pressure Pump*1 | Control System*1, Feed System*1, Blower*1, Induced Draft Fan*1, Wet Dust Collection*1, Economizer*1, High-pressure Pump*1 |

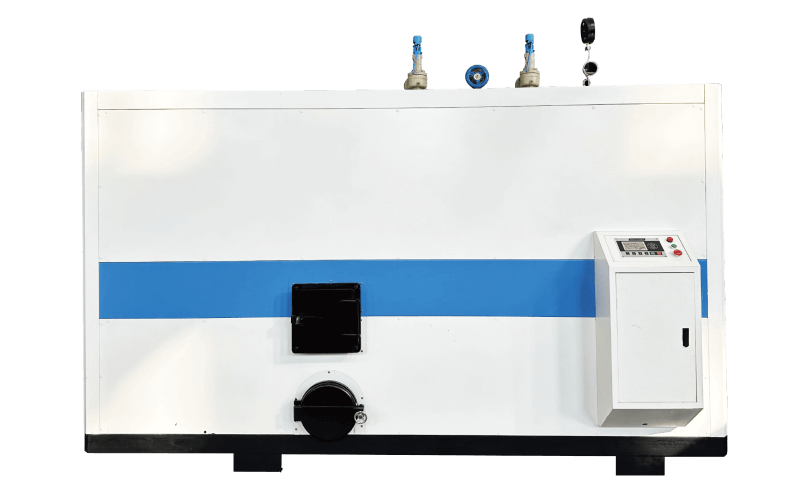

Structure Diagram of Biomass Fired Steam Evaporator