Our worldwide presence ensures the timeliness, cost efficiency and compliance adherence required to ensure your production timelines are met.

Call Us

+88 02 5508 6766Call Us

+88 02 5508 6766H.E. ≥ 95% | NOX ≤30 mg/m3 | Fuel (1 T/h) 160 m3/h |

Product Features

Integrated and compact structure makes boiler easy to install.

Extremely economical, energy-saving, and efficient operation. Low fuel consumption, low nitrogen emission and low-cost operation are realized through the configuration of well-known brand high-efficiency burners, special design on structure, low-NOX controlled combustion process and water supply system with variable frequency conversion.

High strength furnace body, safety is guaranteed. Using a corrugated combusting chamber, screwed fume tube together with wet back structure helps to meet thermal expansion requirements of component and simultaneously increase the rigidity of boiler body.

Efficient thermal insulation. The application of new thermal insulating materials that are light-weight, performance well on heat preservation can reach less heat loss of boiler.

Condensing-heat transfer obtains ultra-high thermal efficiency. One high-efficiency condenser configured on outlet of fume can fully absorb the latent heat of the flue gas, resulting in remarkable energy saving effect. Its thermal efficiency is over 100%.

A water supply with inverter to save electricity. Implementing frequency conversion technology for water supply and its control can result in a fully intelligent water supply that can save up to 40% on electricity consumption.

Using special steel condenser with long service life. In order to prevent acidic corrosion of smoke condensate, the finned tube of the condenser is made of ND steel and other special steel.

Comprehensive protection and safe operation. Control system for overheating, low-pressure, prevention for gas leak and other comprehensive protection ensures long-term steady operation of the boiler while continuously ensuring production safety.

Intelligent control system. Color touch screen PLC control system, easy to operate that allows for multiple group control via a dedicated communication interface.

Easy to maintenance. Set up movable front and rear smoke box with double sealed to make it simple to inspect, maintain, and clean the inside of boiler.

Technical Parameters

Model | WNS1 | WNS2 | WNS4 | WNS6 | WNS8 | WNS10 | WNS12 | WNS15 | WNS20 | ||

Rated Evaporation | T/h | 1 | 2 | 4 | 6 | 8 | 10 | 12 | 15 | 20 | |

Feed Water Temperature | °C | 20 | 20 | 20 | 20 | 104 | 104 | 104 | 104 | 104 | |

Rated Steam Pressure | MPa | 1.0/1.25 | |||||||||

Rated Steam Temperature | °C | 184 / 193.4 | |||||||||

Applicable Fuel | / | Natural Gas / Liquefied Petroleum Gas / Light Diesel/Biogas | |||||||||

Fuel Consumption | NG | Nm3/h | 79 | 148.2 | 288.58 | 444 | 577.4 | 663.3 | 785 | 998 | 1327 |

LPG | Nm3/h | 27.5 | 51.6 | 101.2 | 444 | 577.4 | 663.3 | 785 | 998 | 1327 | |

Light Diesel | kg/h | 27.5 | 130.2 | 259.5 | 390 | 507 | 549 | 787 | 830.6 | 1094 | |

Thermal Efficiency | % | 103 % | |||||||||

Power Consumption | Kw | 5.5 | 9.5 | 14.7 | 22.5 | 37.5 | 44 | 65 | 73.5 | 97 | |

Voltage | V | 220, 380 / 50Hz | |||||||||

Weight | T | 8 | 9.1 | 12.8 | 17.7 | 23.3 | 26.6 | 28.9 | 31.1 | 52.5 | |

Water Capacity | m3 | 3.7 | 6 | 8.6 | 11.2 | 15.3 | 21.0 | 27.5 | 28.7 | 41.4 | |

Emission of NOX | / | ≤150mg/Nm3 / ≤80mg/Nm3 / ≤30mg/Nm3 | |||||||||

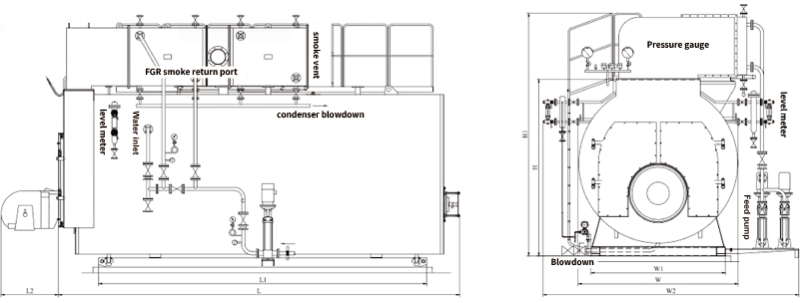

Installation Dimension

Model | WNS1 | WNS2 | WNS4 | WNS6 | WNS8 | WNS10 | WNS12 | WNS15 | WNS20 | |

Inlet Of Water | DN | 25 | 32 | 40 | 40 | 50 | 50 | 50 | 65 | 65 |

Main Outlet of Steam | DN | 50 | 80 | 100 | 124 | 150 | 150 | 200 | 200 | 200 |

Auxiliary Outlet of Steam | DN | 25 | 40 | 40 | 40 | 40 | 40 | 40 | 50 | 50 |

Outlet of Surface Drain | DN | 25 | 25 | 25 | 25 | 40 | 40 | 40 | 40 | 40 |

Base of Safety Valve | DN | 2x40 | 2x40 | 2x50 | 2x65 | 2x80 | 2x80 | 2x80 | 2x100 | 2x100 |

Drain Outlet | DN | 50 | 50 | 50 | 50 | 50 | 50 | 2x50 | 2x50 | 2x50 |

Outlet of Condensate | -- | G2"x2 | ||||||||

Diameter of Chimney | High*Width | 214x350 | 319x350 | 364x500 | 514x500 | 704x740 | 789x700 | 789x700 | 809x880 | 1105x990 |

Overall Size of Product | L | 3680 | 4457 | 5211 | 6125 | 6647 | 7153 | 7528 | 7740 | 8900 |

L1 | 2810 | 3300 | 4200 | 5000 | 5450 | 5860 | 6450 | 6500 | 5800 | |

L2 | Determine Based on the Size of the Selected Burner | |||||||||

W | 2000 | 2074 | 2330 | 2530 | 2696 | 2860 | 3000 | 3300 | 3620 | |

W1 | 1640 | 1500 | 1800 | 2000 | 2200 | 2400 | 2500 | 2600 | 3200 | |

W2 | 3266 | 3367 | 3596 | 3796 | 3990 | 4153 | 4266 | 4271 | 4493 | |

H | 2174 | 2305 | 2597 | 2826 | 3030 | 3230 | 3490 | 3660 | 3970 | |

H1 | 3310 | 3421 | 3718 | 3945 | 4124 | 4325 | 4642 | 5200 | 5450 | |