Our worldwide presence ensures the timeliness, cost efficiency and compliance adherence required to ensure your production timelines are met.

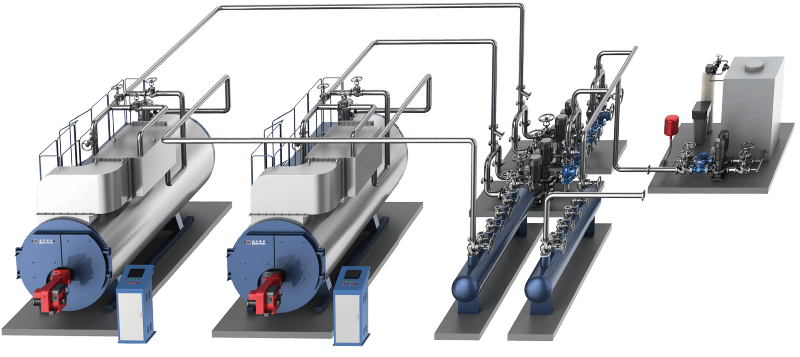

Energy Saving Steam Evaporator

WSS- Series Biomass Fired Steam Evaporator

To provide production steam for food processing factories, printing and dyeing, garment manufacturing, pharmaceuticals, scientific research institutes and so on, to provide sterilization steam for hospitals, to provide steam for other enterprises and hotels, and to heat tanks to provide hot water for daily use.

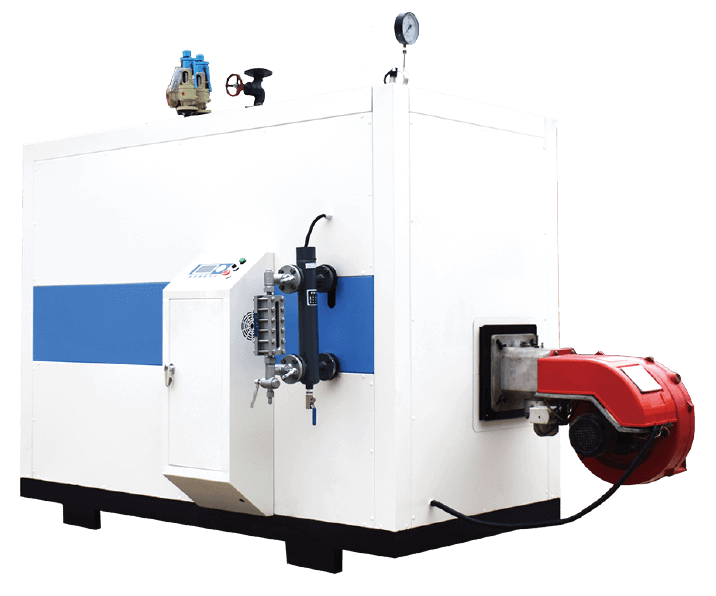

WSS- Series Gas/Diesel Fired Steam Evaporator

A large space furnace with exceptional thermal expansion capability is utilized by the steam evaporator in the combustion chamber, along with an explosion door. To ensure the safe operation of the steam evaporator, the body is equipped with highly sensitive sensors for temperature, pressure, and water level. The controller establishes a highly dependable multiple safety protection control system.

Green & Energy Saving Steam Boiler

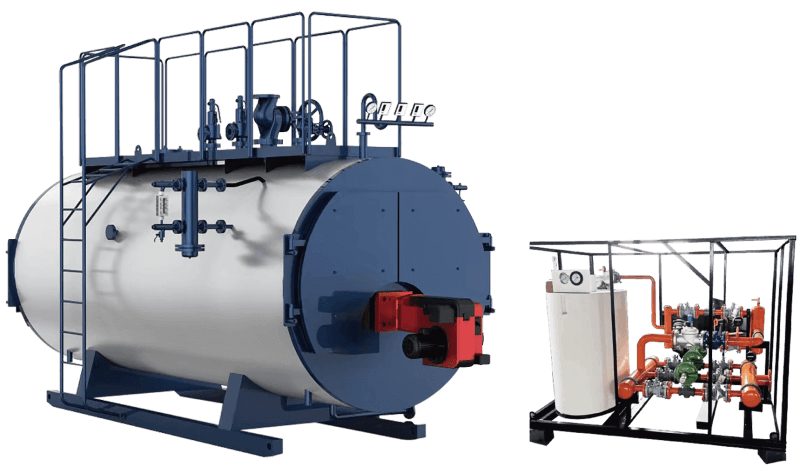

SZS- Series Large Tonnage Gas/Oil-Fired Steam Boiler

The SZS series boiler adopts double-drums (or triple-drums), type-D membrane wall structure. The boiler consists of upper (center) and lower drums, membrane wall of water tubes, convection heat exchanging tube bundle, over-heater, tail economizer, condenser, etc.;

DZL/SZL- Series Biomass/Coal-Fired Energy Saving Steam Boiler

The boiler body adopts double-drum, water tube structure and chain grate combustion mode. The drum is arranged longitudinally along the center of the boiler up and down, the wall of water tubes forms the radiant heating surface of the furnace, the tube group between the upper drum and lower drum forms another convection heating surface of the furnace; and a coal economizer is equipped on the tail of fume.

WNS- Series Dual Fuels (LPG & Diesel Oil) Fired Energy Saving Steam Boiler

Possess all the high thermal efficiency, high safety, low environmental emissions and excellent technical performance of energy-saving gas fired boilers;

WNS- Series Gas/Oil Fired Energy Saving Steam Boiler

Integrated and compact structure makes boiler easy to install;

Gas/Oil-Fired Energy Saving Thermal Oil Boiler

YYL(W)- Series Gas/Oil-Fired Energy Saving Thermal Oil Boiler

The heat exchange surface of thermal oil boiler adopts structure of closer spiral coiled tubes, three return structure of flue gas to optimize the strength of space heat transmission and boost convective heat exchange;

YLW- Series Biomass/ Coal-Fired Energy Saving Thermal Oil Boiler

The YLW series biomass-fired thermal oil boiler is an assembled chain grate (reciprocating grates) boiler with forced circulation combustion. The boiler consists of an upper boiler body and lower grate, which can be assembled and installed on-site. The boiler structure is compact, small footprint, high degree of assembly, a short installation period, and saves costs.

Biomass Co-generation System

Environmental Protection Facility

ESP – Electrostatic Precipitator

The ESP is divided into wet electrostatic precipitator (WESP) and dry electrostatic precipitator (DESP), both of which have the same principle of dust collection. Both rely on high-voltage discharge to make the dust charged, and the charged dust reaches the dust collection plate/tube under the action of the electric field force.

DST - Desulfurization Tower

The GCT type high-efficiency desulfurization spray tower is a new type of high-efficiency spray tower designed by our company for flue gas desulfurization. Based on the original manufacturing process change the internal structure of the equipment, lined with granite anti-corrosion liner, increase the amount of spray circulation, reasonable placement of the nozzle position to improve the efficiency of desulfurization, to extend the service life. It has passed the inspection and acceptance of the Administration of Environmental Protection of China. The expected service life is designed for over 20 years.

Dust Collector Bag

The LCM-D/G series low-pressure long-bag pulse dust collector is a new type of high-efficiency bag filter. It not only synthesizes the advantages of compartmentalized back blowing and pulse blowing, but also lengthens the filter bag, giving full play to the role of compressed air blowing under low air pressure (blowing pressure 0.15-0.3MPa). It overcomes the shortcomings of low intensity of chamber back blowing, pulse blowing and dust filtration at the same time, and prevents dust from re-adhesion and out of control, which improves the filtration speed, decreases the energy consumption of dust cleaning and prolongs the service life of the filter bag.